DREAM and READI: Cooperation to Manage Digital Requirements

The oil & gas industry is built around a set of specifications, standards and recommended practices, and many of these have been developed and are maintained by DNV GL. Digital transformation has implications for how these standards and published, shared and used. Currently DNV GL’s portfolio contains about 800 different requirement documents related to our focused business sectors. As a first step in digitalization, these documents have been converted from text into XML. This means that requirements are translated from unstructured text to structured text. This improves document and requirement management processes, but does allow us to exploit the full benefits of digital transformation.

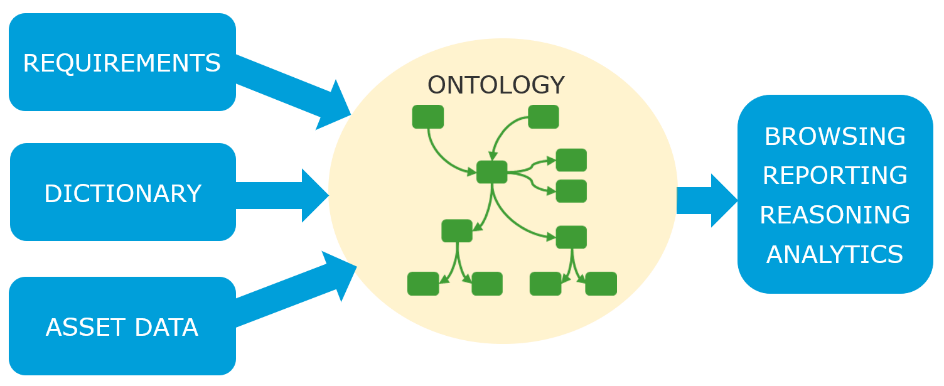

DNV GL spends about 5% of its revenue on research, innovation and business development. In 2018 the DREAM (Digital REquirements and Assurance Management) project was sponsored by an internal research programme. This project investigated how concepts, methodology and tools developed by a joint SIRIUS and NORSOK Z-TI initiative in 2017 could be applied for full digitalization and management of DNV GL’s portfolio of requirements. Close cooperation with SIRIUS was initiated. Methods, tools and demonstrators were further developed for testing based on real use cases in the maritime, oil & gas and energy sectors. We worked with domain specialists from each sector to select, review and test selected sets of requirements and represent them in a new format that allows computers to perform automated reasoning. In this way, we can check automatically if requirements are met, how they related to data about a project and whether they are consistent. This digital format also allows storage and sharing of requirements in data bases. This initial work was promising and has resulted in the DREAM tool: a framework for representing requirements in a fully digital form. The principle behind this tool is shown in the following figure. Relevant requirements, asset data and definitions are all implemented in a knowledge model – an ontology. This representation, stored in a suitable database, allows computer programs to browse, evaluated, validated and analyse requirements with a precision that is impossible with paper documents.

The challenge of digitalizing requirements reaches far outside DNV GL. The Norwegian Oil & Gas industry’s KONKRAFT initiative seeks ways to reduce cost and improve effectiveness in operation. A strategy report in 2017 identified reduction of paper and duplication as a vital aspect of digitalization. For this reason,

KONKRAFT set up a Joint Industry Project (JIP) called READI in mid 2018. READI is an acronym for Requirements Asset Digital Information. The knowledge, experience and products available from the NORSOK Z-TI pre- project and the DREAM project made DNV GL a natural choice to coordinate and manage this project. This joint project involves other SIRIUS partners, Equinor, TechnipFMC, Computas, Aker Solutions and Aibel, as part of a wider group of engineering and operating companies.

The READI project works on the digitalization of NORSOK standards. The NORSOK technical information standards intended to ensure common practices and rules for information exchange and ownership throughout the life cycle of oil & gas assets. They stated principles for digital information to be accepted as a project deliverable, specified ownership for the project information generated in the various project phases and defined the responsibility to secure quality and accessibility to such information to allow concurrent engineering processes involving several organizations.

Phase 1 of READI is updating and converting five NORSOK standards for management of technical information. These standards were written in the mid 1990s, with the ambition of reducing capital cost and improving collaboration. They have, for more than two decades, led to a shared understanding of the information that needs to be organized and circulated between the parties in a field development project. However, each operating company has developed different practices and detailed requirements specifications. This results in practices where the contractors and manufacturers have to use different requirements and associated work processes from project to project. The industry suffers from superfluous and inconsistent requirements and a very high cost for production and management of the documents and information needed.

READI builds on previous work done in a JIP, run by EPIM, called STI. This project established a common industry understanding of the necessary documents to be delivered for all types of equipment. It delivered its result as planned at the end of 2018. One of the five NORSOK standards to be revised by READI, Z-018-Supplier’s documentation of equipment, will continue of the work done by STI. For another standard, NORSOK Z-001 Documentation for Operation, READI builds on a DNV GL recommended practice DNVGL-RP-O101, Technical documentation for subsea projects, which STI had also adapted for vendor documentation requirements. READI will digitalize the requirements from this recommended practice. The project will combine the requirement converted into a digital representation with asset data from existing subsea installations. This allows us to investigate and demonstrate possibilities and effects of automatic requirement verification. The tools for this are tailor-made tools in READI and are all developed with significant contribution from SIRIUS. This involves the use and further development of templates for mapping requirements, dictionary and asset data formats from their sources to the READI knowledge model. This is done by using the OTTR templates (see the SIRIUS 2017 annual report for a description of OTTR).

It is demanding and labour intensive to convert a requirement from text to a digital format. A human is needed to do this translation. Natural Language Processing (NLP) can allow us to convert of text-based requirements to digital requirements automatically. Text requirements often contain patterns that can be used in NLP. This work builds on the tools under development in the Data Science research programme.

Digitalization of requirements will not save money unless it is used as a way of digitalizing work practices. For this reason, the READY JIP is working with Mina Haghshenas, a PhD student from NTNU and SIRIUS’ program for Industrial Digital Transformation. She participates in the daily work tasks in the JIP and uses the project as a research case in her study of the organizational aspects and effects of running a large Joint Industry Project like READI.